The company Faust Linoleum offers linoleum products for office and home surroundings, like tabletops, shelving systems, stools and pin boards. All these products focus around the material ... more

The company Faust Linoleum offers linoleum products for office and home surroundings, like tabletops, shelving systems, stools and pin boards. All these products focus around the material ... more The production

An intelligent and sustainable ecosystem

The colorful linoleum crew

Idyllically situated in the Upper Bavarian village Huglfing, specialists from different countries come together to bring some big-city flair into our little village. Every day at 9 a.m. our Sardinian colleagues distribute strong and fragrant espresso, which they cook in the “caffettiera” in a traditional manner. Surrounded by glacial hills and valleys, there is no room for rush at Faust Linoleum. Much to our delight, our Italian chef also provides us with freshly prepared international dishes every day. So we start our lunch together by saying “Mahzeit” which means “Enjoy your meal” in Bavaria. In a lively exchange of information over short, unbureaucratic paths, we find a satisfactory solution even for complicated projects.

The ecological production line of the linoleum board

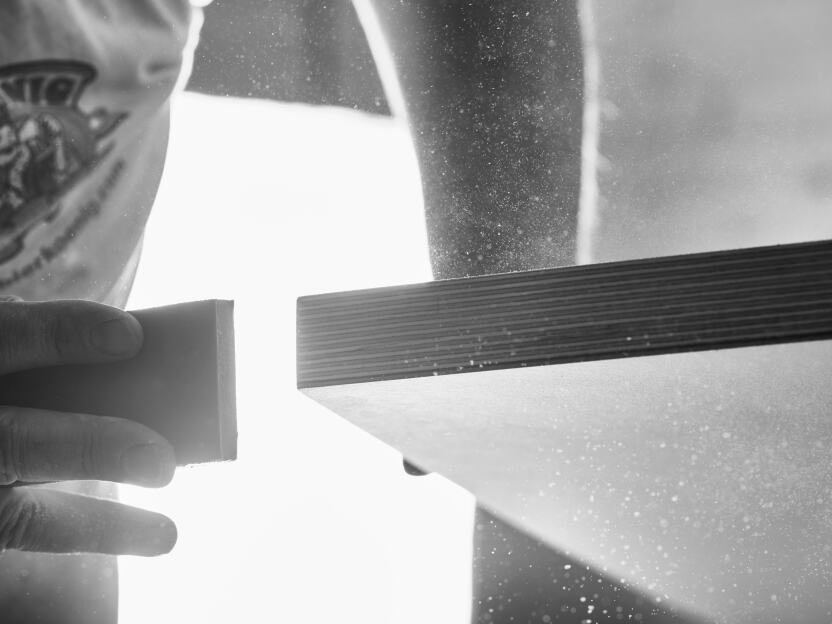

About 10 finely tuned stations are needed to produce the perfect Faust linoleum tabletop. These stations are managed by skilled craftsmen using high-tech machines. The raw material is cut exactly to the customer’s specifications, accurate to the millimeter, and the cut-outs are milled by 5-axis CNC machines. Offcuts and remnants can be reduced to a minimum and are fed to the internal wood chips plant for the company’s own heat recovery. More than half of the energy required is obtained from our photovoltaic system on the roof of our production facility, additional power is purchased from green energy suppliers.

The production stations of a linoleum tabletop

The specifications of our linoleum tabletops are transferred directly into our PLM database via our online configurator. We start the production after a careful check by our carpenters. Each production step is individually documented and can be traced at any time. First the base material and the linoleum are cut to size. The edging has to be added before the tabletops are put into the press. Depending on the configuration, cut-outs for cable management or special cut-outs are applied on the tabletop afterwards. After the edges have been oiled, the linoleum boards are finally subjected to a thorough quality inspection and packed for a safe transport. To ensure that the tabletops are delivered in perfect condition, we deliver them ourselves. Our professional drivers start in Huglfing and drive across Germany in a specially equipped transporter to deliver to our customers all over Germany. In addition to deliveries within Germany, we also organize deliveries to Austria, Denmark, the Netherlands and the Benelux countries. Thanks to our well-developed transport system, we can arrange and carry out the deliveries highly flexible. We are well organized, so you can plan better.